Tests Highlight Seismic Resilience of Tall Mass Timber

Jun 16, 2023

WoodWorks

Key Takeaways

- In May, a 10-story building made of cross-laminated timber (CLT) underwent testing on the world’s largest outdoor shake table at the University of California San Diego. The goal? To validate the capacity of tall mass timber buildings to withstand seismic events.

- This project could pave the way for changes in building codes for residential and commercial structures that could lead to more widespread adoption of mass timber—especially in areas prone to seismic activity.

- It could also validate mass timber and other innovative technologies as vehicles to help make buildings safer and more resistant to earthquake activity.

- WoodWorks has resources and education available to get you up to speed on what this means for mass timber building design.

10-Story NHERI Shake Table Test: State of the Art Mass Timber Seismic Design

On May 9th, a 10-story building made of cross-laminated timber underwent testing on the world’s largest outdoor shake table, funded by the National Science Foundation (NSF), at the University of California San Diego (UCSD). The structure was constructed to undergo testing as part of the Natural Hazards Engineering Research Infrastructure (NHERI) TallWood Project, an industry-wide initiative that investigates the seismic resilience of mass timber and the extent of its potential use as a low-carbon structural material.

This testing culminates years of collaboration between a long list of universities, industry partners, design and construction partners, and non-profit partners—including WoodWorks, Think Wood, the Softwood Lumber Board (SLB) and the Binational Softwood Lumber Council (BSLC)—who have worked together to further mass timber innovation. The principal investigators include researchers from the Colorado School of Mines; the University of Washington; the University of Nevada, Reno; Colorado State University; Washington State University; and Lehigh University.

“Mass timber is already known globally as a sustainable, low-carbon building material,” shared Cees de Jager, President and CEO of the SLB and BSLC. “These tests will prove mass timber’s viability as a safe and effective, as well as sustainable, alternative to steel-and-concrete buildings in seismically active areas, paving the way for broader adoption in taller mass timber structures nationwide.”

The UCSD shake table, where the testing is taking place, recently underwent an upgrade that increased the number of axes of shake—allowing it to better simulate actual seismic events. Utilizing a mass timber rocking-wall system, the structure was designed to withstand high-magnitude earthquakes and incur little to no structural damage. In the initial tests, the building underwent simulations of two of the most destructive earthquakes in recent history. The first test was equivalent to the 6.7 magnitude 1994 Northridge earthquake, and the second to the 7.7 magnitude Chi Chi earthquake that took place in Taiwan in 1999. Following each simulation, researchers assessed the building for damage.

In an interview with UCSD, Shiling Pei, associate professor at Colorado School of Mines and lead investigator on the NHERI Tallwood Project, said, “It performed exactly as we expected—the building remained damage free after two major design-level earthquakes back to back.”

Engineering News Record details the technical achievement of the rocking-wall system, talking with Reid Zimmerman, structural technical director of the Portland, OR office of KPFF Consulting Engineers, and a member of the TallWood design and construction team. “For post-tensioning, the rocking walls each have two high-strength threaded bars running full height, which precompress the CLT panels or mass plywood panels. At the bottom of the walls, the rods anchor into the foundation. At the top of the walls, the rods attach to a steel “saddle” assembly which transfers the load from the threaded rods into the mass timber wall panels. During shaking, the mass timber panels rock, lifting at the heel end and compressing at the toe end of the walls, while always controlled and brought “back to center” by the post-tensioned rods.”

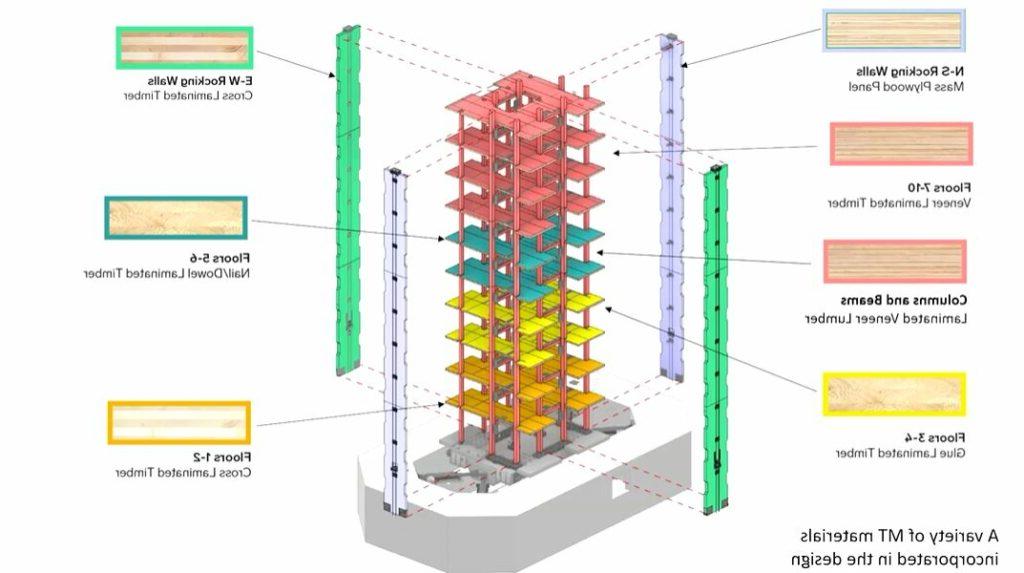

Designed by LEVER Architecture, the TallWood project structure stands 112-ft-tall, with four partial façade assemblies. It contains several mass timber products in the floors, walls, columns and beams, including cross-laminated timber (CLT), glue-laminated timber, laminated veneer lumber (LVL) or nail/dowel laminated timber panels, depending on the level.

“This test series demonstrated how a tall mass timber seismic system is can withstand multiple, very high seismic events,” said WoodWorks Senior Technical Director Scott Breneman, PhD, PE, SE. “Coming into these tests, years of component and system tests and thousands upon thousands of computerized earthquake simulations gave the research team the confidence that the tests would pass—but seeing the building pass the actual tests on the NHERI 3-D shake table was a once-in-a-lifetime experience for me. I congratulate Shiling Pei and the extended research and industry team for this achievement.“

“Seeing the building pass the actual tests on the NEHRI 3-D shake table was a once-in-a-lifetime experience for me. I congratulate Shiling Pei and the extended research and industry team for this achievement.’’

– Scott Breneman, PhD, PE, SE, WoodWorks Senior Technical Director

What is the motivation for a research project of this scale?

The NHERI Tallwood Project could impact forthcoming building codes for residential and commercial structures, leading to more widespread adoption of mass timber as a sustainable, strong, and versatile building material—especially in areas prone to seismic activity. It could also validate mass timber and other innovative technologies as vehicles to help make buildings safer and more resistant to earthquake activity.

There are 11 tall wood projects built or under construction in the US, and nearly all of them have a non-timber lateral system, utilizing steel and concrete in their core for a hybrid design solution. The NHERI TallWood Project and associated testing can validate an all-timber solution for lateral systems—giving designers, developers, and owners another way to expand their use of mass timber to their project’s advantage. Hybrid systems, as seen on the completed tall wood projects, have proven effective and will remain a good option in many cases. However, utilizing an all-timber system would maximize the benefits of mass timber on a project—such as lower carbon impact, less coordination between materials, fewer trades on site, and a shorter construction time. An all-timber system like the one being tested would also offer increased resilience with better performance capabilities than structures designed to current code minimums.

At the conclusion of the project, shared Pei, researchers will provide design and construction guidelines for the rocking-wall system, with the goal of having it recognized in building codes. Jonathan Heppner, LEVER’s principal for the test frame, shared that even before the rocking wall system is incorporated into the design guidelines, the research “will help with the permit approval process.”

Look for the full findings of the building testing to be published. Already available is the article Prescriptive Seismic Design Procedure for Post-Tensioned Mass Timber Rocking Walls, co-authored by Pei and five others, which appeared last year in the ASCE Journal of Structural Engineering.

The Details of Seismic Design: WoodWorks Education and Resources

Following the initial day of testing, WoodWorks hosted an invite-only event at the testing site. The program covered a gamut of information on the subject, including a comprehensive overview of current seismic design options within the International Building Code (IBC), implementation of the new CLT shear wall system and structural CLT diaphragms permitted in the 2021 SDPWS, mechanisms of the mass timber rocking-wall system, and unique design attributes of the 10-story mass timber structure.

The day’s highlight was the shake table testing itself, which offered attendees a rare opportunity to witness the behavior of mass timber structures during seismic events, and to visualize the application of seismic design principles discussed during the workshop.

The course, titled State of Art Mass Timber Seismic Design and the 10-Story NHERI Shake Table Test is accredited and available now on The Wood Institute website.